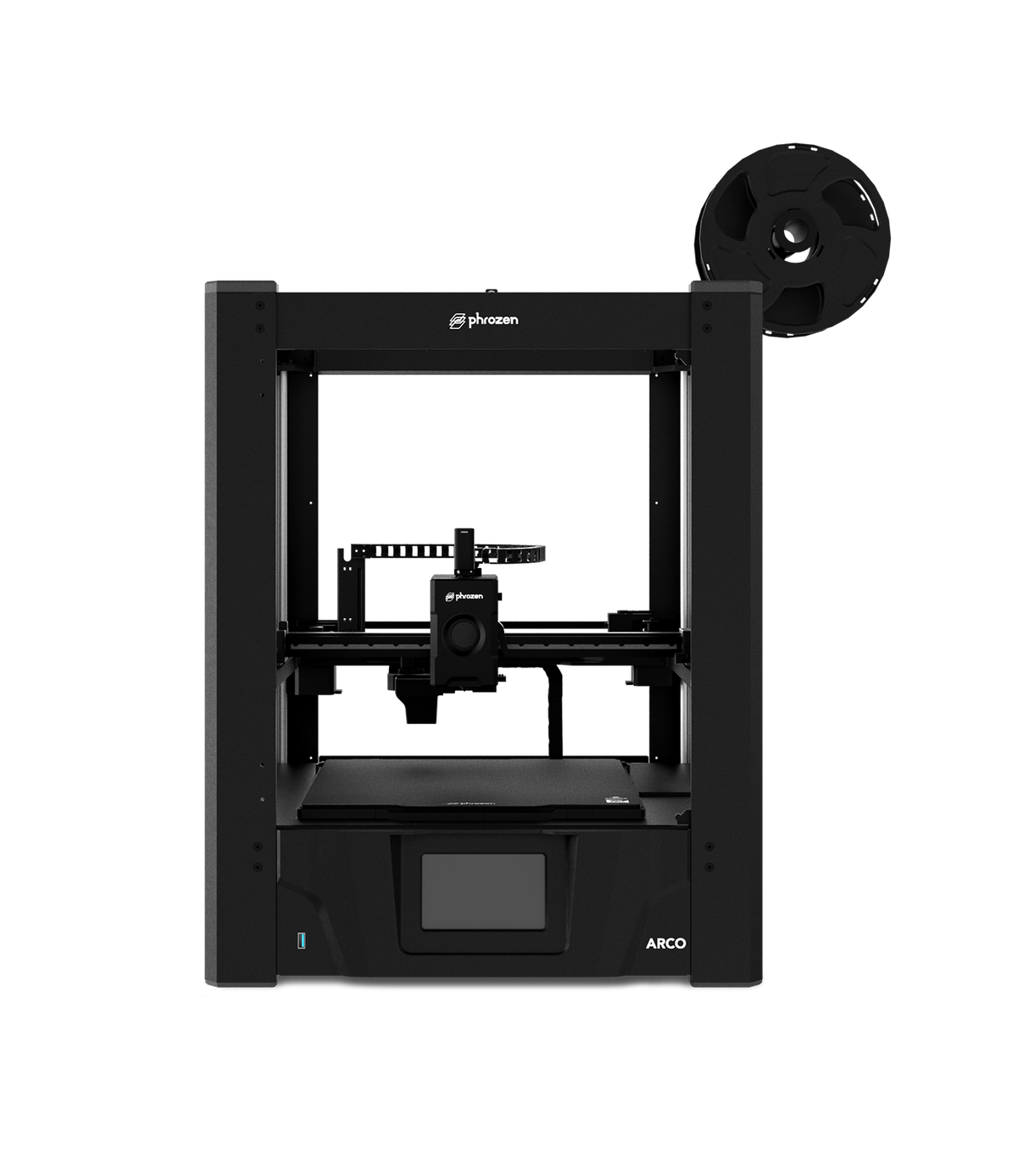

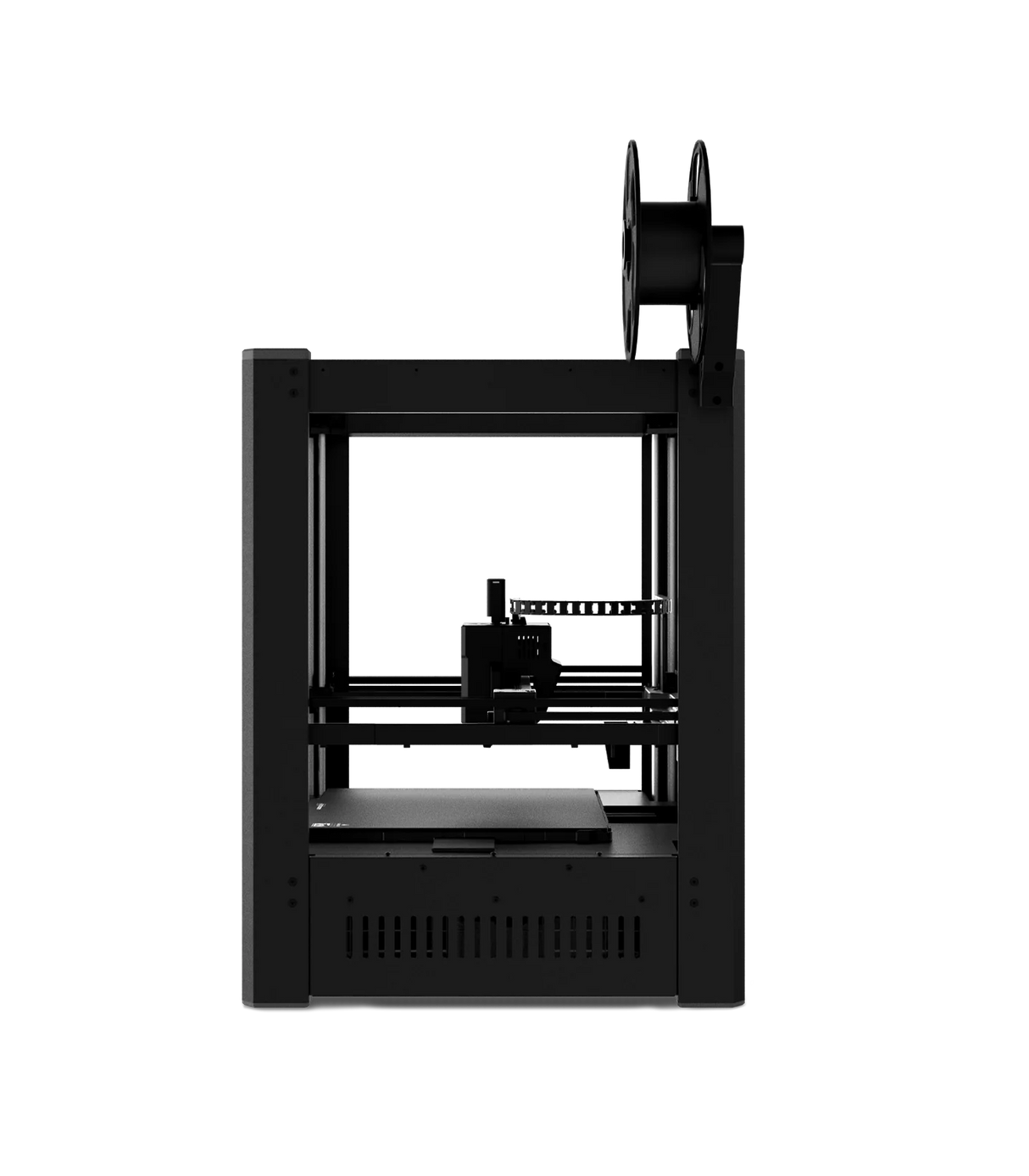

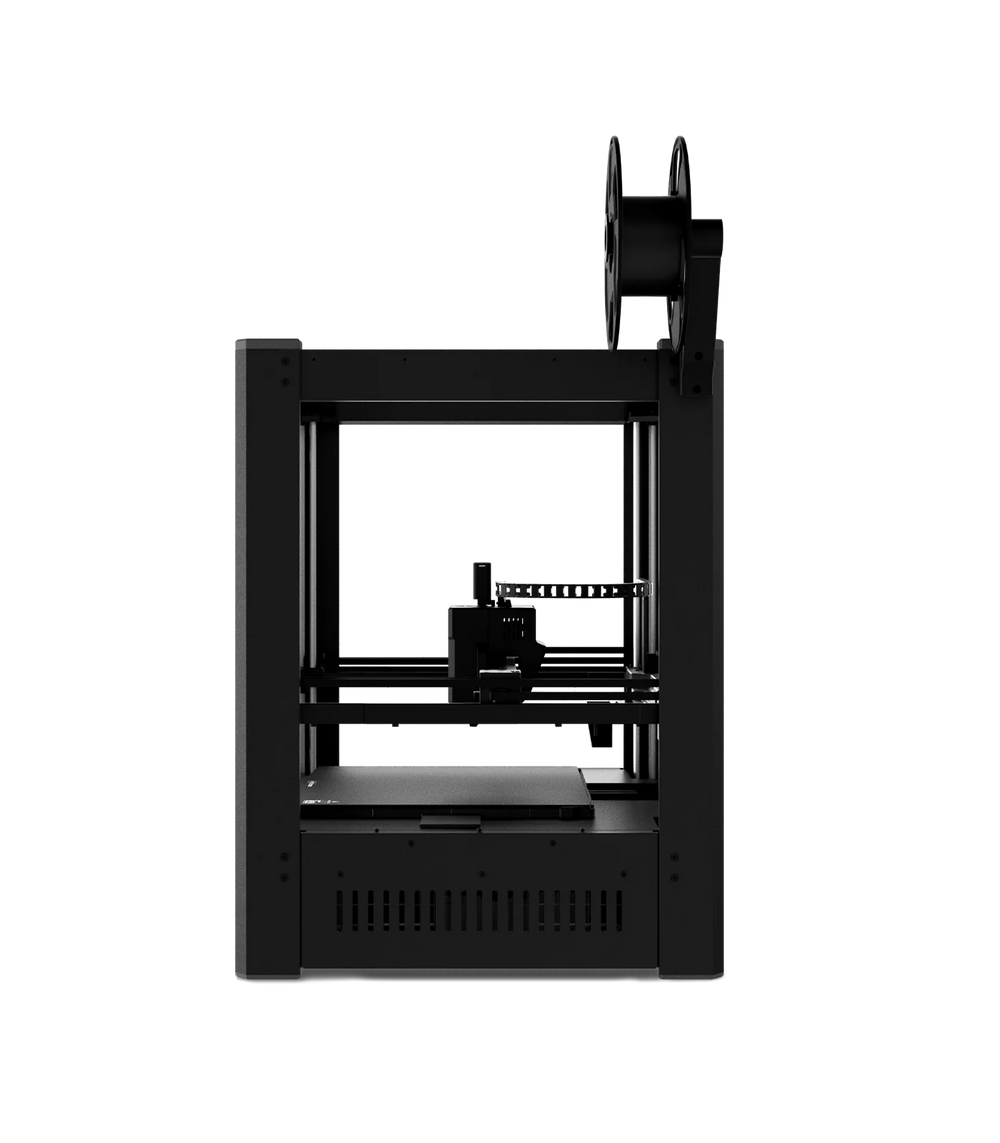

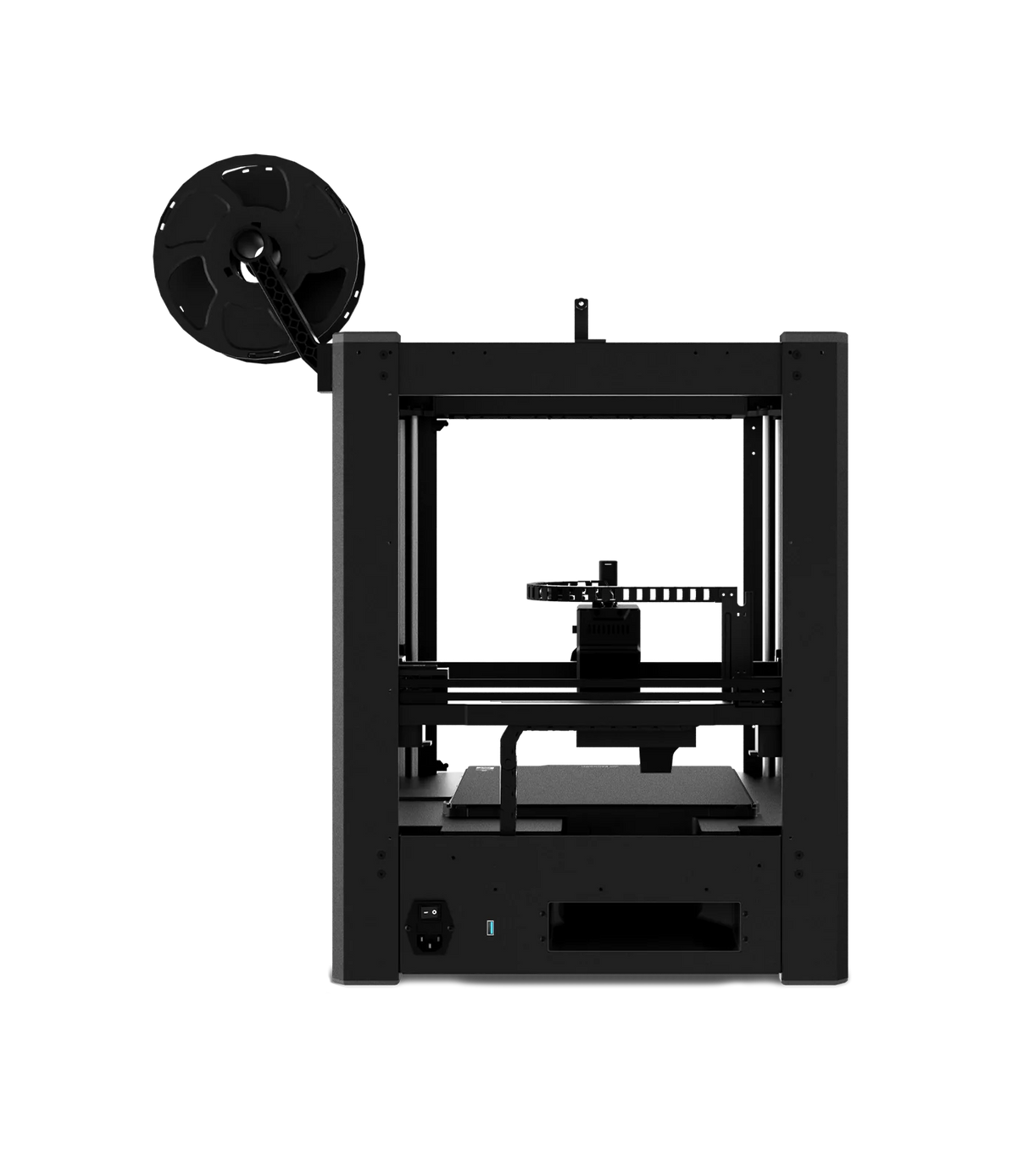

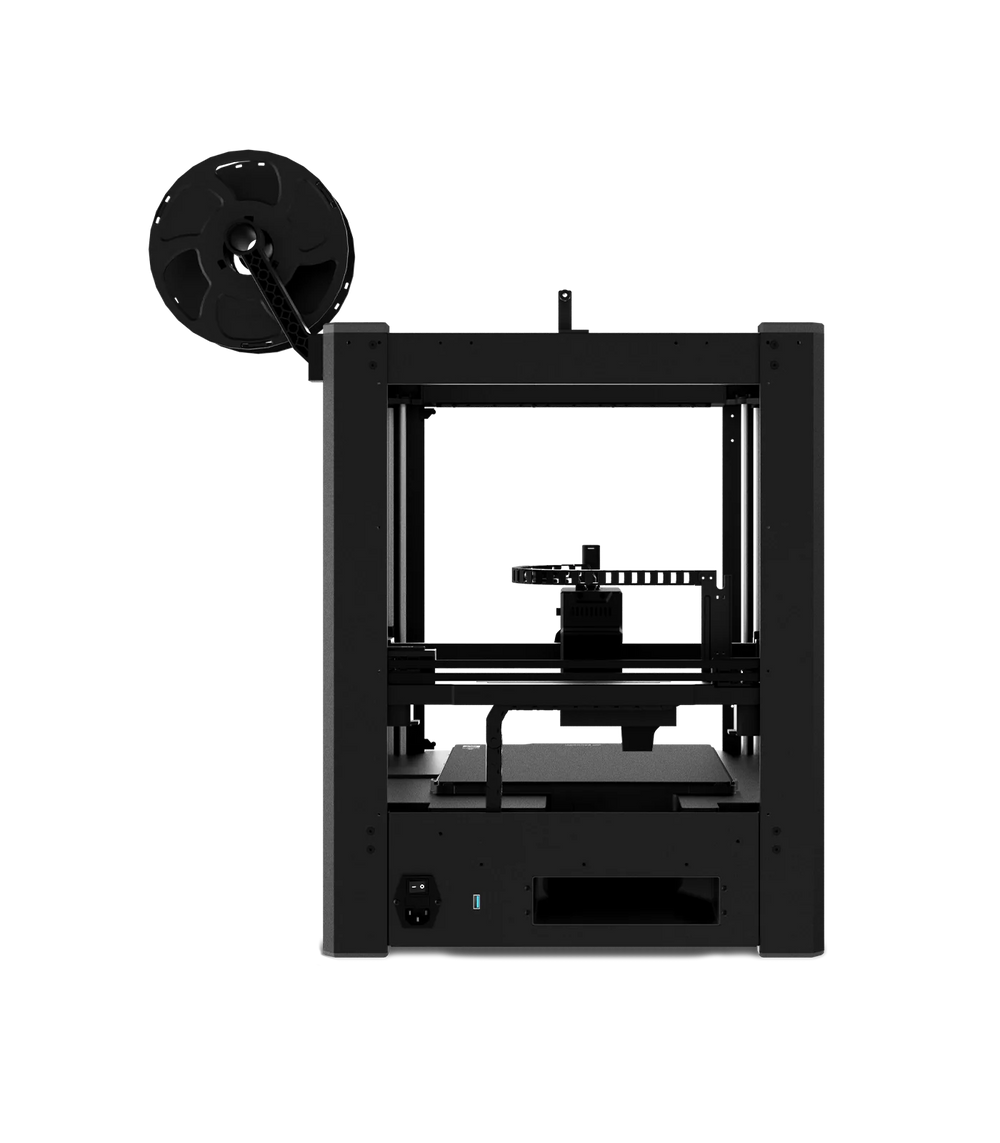

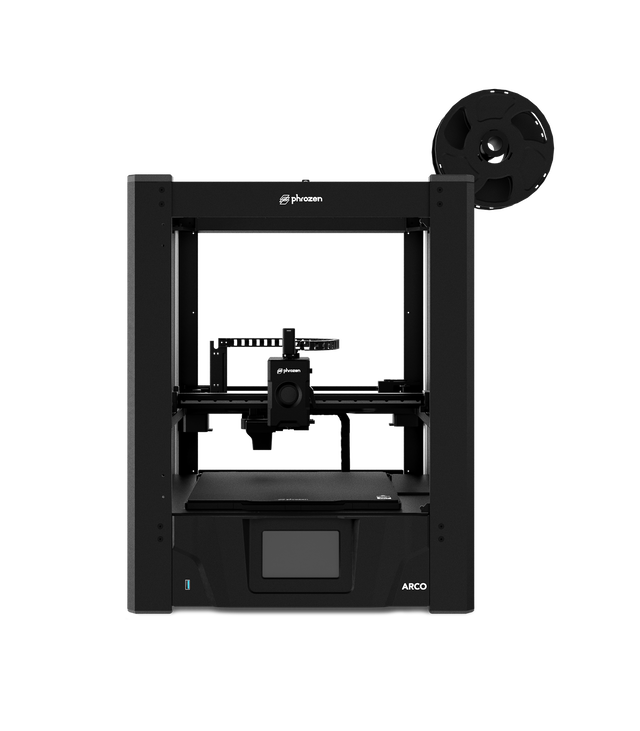

Phrozen Arco FDM 3D Printer

- 300 × 300 × 300 mm Build Volume — Print large models in one piece.

- 4 Dedicated Flament Tubes — Switch colors 50% faster.

- 3 Pro-Grade Nozzles — Includes high-speed, high-flow, and abrasion-resistant types.

- Complete Starter Kit — Ready to print

from day one.

Couldn't load pickup availability

Shipping & Tariff

- Please expect a standard lead time of approximately 1 week.

- Currently, the Phrozen US Store only ships to the mainland United States. For non-contiguous states and other U.S. territories, please purchase through our Global Store.

- No refunds will be provided if a customer refuses to collect or returns their product(s) due to related costs.

- Customers are responsible for customs clearance in all countries.

- For more information, please refer to our Shipping page.

Shipping Notice: In-stock items are prioritized and arranged to ship first. Out-of-stock items will ship once available.

Return & Warranty

- According to the Consumer Protection Act, you have the option to request a refund within a period of 13 days. However, please note that the refund does not cover the shipping fees and tax/VAT charges. To initiate the refund process, you need to submit a request to the Phrozen Support Center within this 13-day timeframe. It is important to ensure that the product is returned in its original condition, and the entire batch order must be sent back. For more details, please refer to our Refund Policy page.

-

All products purchased from the official website of Phrozen are warranted under different terms. Phrozen offers a one-year warranty for all our products except consumables and components; this includes the LCD screen and the FEP film. LCD screens for the Sonic Mighty 8K, Sonic Mini 8K, Sonic Mega 8K, Sonic Mini 4K, and Sonic 4K are covered under a 3-month warranty. For more details, please refer to our Warranty page.

*Kind reminder: We would suggest pairing our printers with Phrozen's resins to prevent surface paint damage. If a problem occurs, please feel free to contact our support team.

Specifications

Specifications

-

Printing Volume300 x 300 x 300 mm

-

FrameworkCoreXY

-

Single / Multi-ColorMulti-Color Compatible

-

Printing Speed*Up to 1,000 mm/s ; acceleration up to 40,000 mm/s²

-

Maximum Hotend Flow Rate*50 mm³/s

-

Maximum Heated Bed Temperature110°C

-

Maximum Nozzle Temperature300°C

-

Printing Power900W

-

Power Requirement100–240V AC ; 50-60 Hz

-

System Type (Firmware)Klipper

-

SlicerPhrozen Orca | Orca Slicer | PIXUP FDM Slicer

-

Display Screen5-inch Touch Panel

-

Supported FilamentPLA: Supported.

PET/PETG: Supported.

ABS: Supported; recommended to print with the PentaShield.

TPE/TPU: Supported; recommended to print with the CHT high-flow nozzle.

PA (Nylon): Supported; recommended to print with the PentaShield.

PP: Supported; recommended to print with the PentaShield.

PC (Polycarbonate): Supported; recommended to print with the PentaShield and a wear-resistant nozzle.

Carbon / Glass Fiber Reinforced Filaments: Supported; recommended to print with the PentaShield and a wear-resistant nozzle. -

ConnectivityWi-Fi I USB

-

Assistance FeaturesBuilt-in Camera: Resolution 720p, 150° Wide Angle Lens

Material Breakage Detection: Supported

Printing after Power Outage: Supported -

Machine Weight22 kg/48.5 lbs

-

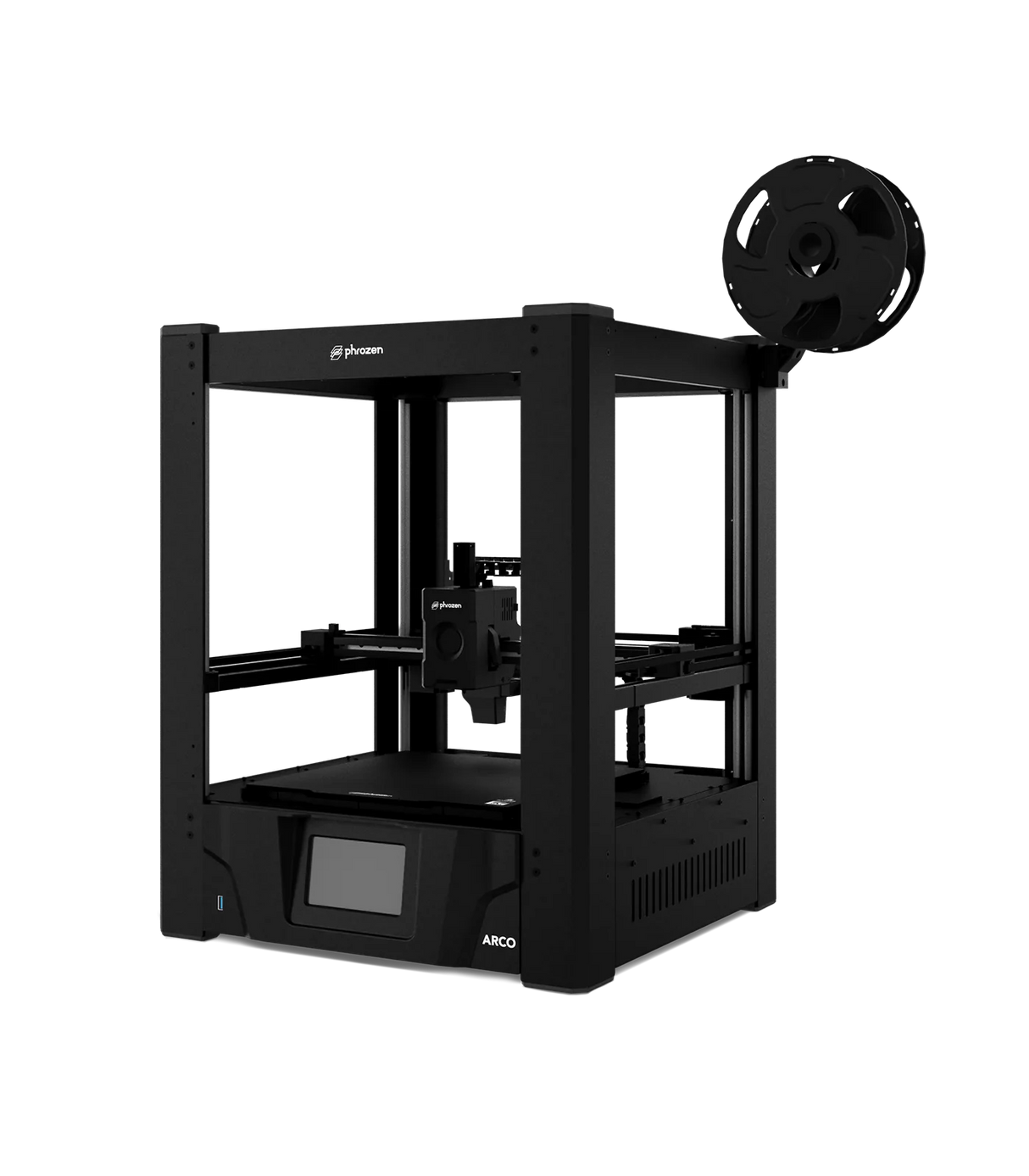

Measurements492 x 475 x 620 mm

19.3 x 18.7 x 24.4 inches

Industrial Grade Cooling

300mm³ Large Printing Volume

Versatile Software Compatibility

Aerospace-Grade Alloy

Fast Multi-Color Swapping

One-Piece

Flying Gantry

Removable Protective Enclosure

High-Speed, No Wobble

Breaking Away from Traditional Moving-Bed Designs

Engineered from the Ground Up for Total Stability

Most CoreXY printers move the heatbed during printing, which causes the model to shake. ARCO uses a fixed heatbed that keeps the print steady while its flying gantry lifts the printhead with precision. Like an F1 car accelerating with perfect control, ARCO delivers both speed and stability in every layer.

Arco Reinforces Stability Right from Its Structure

Typical FDM Structure

- Model moves with the bed, causing wobble.

- Unstable center of gravity.

- Large prints often fail.

- Higher risk of layer shifts and stringing.

ARCO’s Optimized Structur

- Model stays fixed on a stable, non-moving base.

- Low center of gravity for ultra stable printing.

- High success rate, even with large-scale models.

- Lower risk of layer shifting and stringing.

Details Matter. ARCO Delivers Rock-Solid Stability

Solid Build

Full-Body Aerospace Aluminum Frame

ARCO is built with 6000-series aerospace-grade aluminum. Four T-type lead screws and reinforced columns add strength and rigidity for consistent performance at high speeds.

Stable Motion

One-Piece Flying Gantry with XY Linear Rails

An all-metal flying gantry combined with precision XY linear rails ensures smooth travel and precise movement across every axis.

Uniform Heat

4-Layer Heated Bed with Over 90% Heat Uniformity

The bed reaches 100°C in just 2 minutes. With over 90 percent heat distribution, it helps prevent warping and keeps large prints firmly in place from the first layer.

ARCO: Big. Fast. Unstoppable

300 × 300 × 300 mm Large Printing Volume | Max Print Speed: 1,000 mm/s* | Acceleration: Up to 40,000 mm/s² | Max Flow Rate: 50 mm³/s

Keep Up with Your Inspiration — Design It, Print It, Done Fast

Raining? Print New Slippers at Work and Walk Them Home After

Hit Send Before Bed, Wake Up to a Castle — Printed Overnight

Keep Up with Your Inspiration — Design It, Print It, Done Fast

Raining? Print New Slippers at Work and Walk Them Home After

Hit Send Before Bed, Wake Up to a Castle — Printed Overnight

隨時跟上設計靈感,開會完就火速交件

- 300×300×300 mm 大體積列印空間

- 最大列印速度可達 1000 mm/s

- 加速度高達 40000 mm/s

- 最大流量 50 mm³/s

*搭配 CHT高流量噴嘴與普羅森高速PLA, 0.2 mm 層高

雨天上班,下班印好拖鞋直接穿回家

睡前丟檔案,一夜就把城堡蓋好

- 300×300×300 mm 大體積列印空間

- 最大列印速度可達 1000 mm/s

- 加速度高達 40000 mm/s

- 最大流量 50 mm³/s

*搭配 CHT高流量噴嘴與普羅森高速PLA, 0.2 mm 層高

*With CHT® high-flow nozzles and Phrozen high-speed PLA, 0.2 or 0.1 height.

Details Matter. ARCO Delivers Rock-Solid Stability

ARCO is the first to bring patented industrial-grade heat pipe technology to FDM printing. Paired with a huge 18 mm gear, this system cools efficiently and shortens the distance between the extrusion gear and nozzle, delivering stronger torque and higher flow for smoother, clog-free printing.

ARCO DEP Extrusion: High Stability, Maximum Precision

Standard Extrusion

- Longer extrusion path.

- Frequent extrusion issues.

- Smaller gears lead to weaker torque and low flow.

- Quality varies with different materials.

ARCO DEP Extrusion

- Ultra-short extrusion path.

- Smooth and more precise extrusion.

- Larger gears provide stronger torque and higher flow.

- Consistent quality across a wide range of materials.

4-Tube Direct Feed for 50% Faster Color Swaps

Unlike standard 4-in-1-out systems that constantly load and unload filaments, ARCO uses four dedicated tubes that feed directly into the print head. This streamlined setup speeds up color changes by 50 percent and reduces print interruptions. Enjoy smoother multi-color printing and focus more on creating, not waiting.

Flexible Enclosure for a Quieter, Cleaner Print Environment

ARCO’s upgraded five-piece steel enclosure reduces noise by 15%, filters odors with an activated carbon filter, and maintains steady airflow with smart temperature control—optimized for five filament types. Choose automatic fan adjustment or switch it off for special prints. The top cover accommodates multi-color modules, saving space and streamlining setup.

ARCO Premium Nozzle Options for Every Print Job

Bondtech CHT®

Tri-Channel Design for High-Speed Printing

Designed by Bondtech, the CHT® nozzle uses a triple-channel molten core to boost melting efficiency. It supports flow rates up to 50 mm³ per second, making it ideal for fast prints and large-scale models.

SE GammaMaster®

Durable Coating with Excellent Heat Transfer

Created by Slice Engineering for ARCO, the GammaMaster® combines a hardened alloy, Low Gamma™ coating, and copper-based core. It offers strong wear resistance and high thermal conductivity, perfect for long jobs and abrasive filaments.

Phrozen Standard

Stable Heat Conduction for Everyday Printing

Perfect for daily use with PLA, PETG, and other common filaments. This nozzle delivers reliable heat transfer and steady performance across your regular print jobs.

Get Started with ARCO. Easy Setup, Zero Hassle

ARCO comes with everything you need to print confidently. From setup to your first finished model, our tools and guides help you get started fast and stay on track.

-

![]()

PIXUP Marketplace

Access Phrozen’s curated library of high-quality 3D models. Just download and start printing.

-

![]()

Phrozen Orca Slicer

A special version cooked up by Phrozen and Orca. Built on the full Orca setup but fine-tuned for Phrozen machines. Smooth, stable connection with ARCO and Chroma Kit, plus full support you can count on.

-

![]()

Klipper System

Powered by the popular Klipper firmware trusted by advanced makers, ARCO gives you full access to open settings, letting you push performance to the limit.

*Change settings carefully to avoid mistakes that might cause the printer to work incorrectly. -

![]()

Orca Slicer

Fully supported by ARCO and a favorite among FDM fans. Whether you’re rocking single-color or multi-color prints, your workflow stays smooth and hassle-free.

-

![]()

PIXUP FDM Slicer

Phrozen’s own slicing software, built from the ground up. Everything’s optimized for a clean, simple, and seamless printing experience.

-

![]()

Complete Support

Our video tutorials and expert support team are here to guide you at every step, so you can print with confidence right out of the box.

Media Spotlight

ARCO Specifications

- Technology: FDM (Fused Deposition Modeling)

- Structure: CoreXY Fixed Print Bed Structure

- Color Support: Multi-color compatible (requires Chroma Kit)

- Print Volume: 30.0 × 30.0 × 30.0 cm

- Max Print Speed / Acceleration: 1,000 mm/s; Max 40,000 mm/s² acceleration

- Max Flow Rate: 50 mm³/s (CHT nozzle)

- Print Bed Material: High-temperature dual-sided textured PEI print bed

- Max Heated Bed Temperature: 110 °C / 230 °F

- Software: Phrozen Orca/ Orca Slicer/ PIXUP FDM Slicer, Wi-Fi / USB file transfer, .gcode format