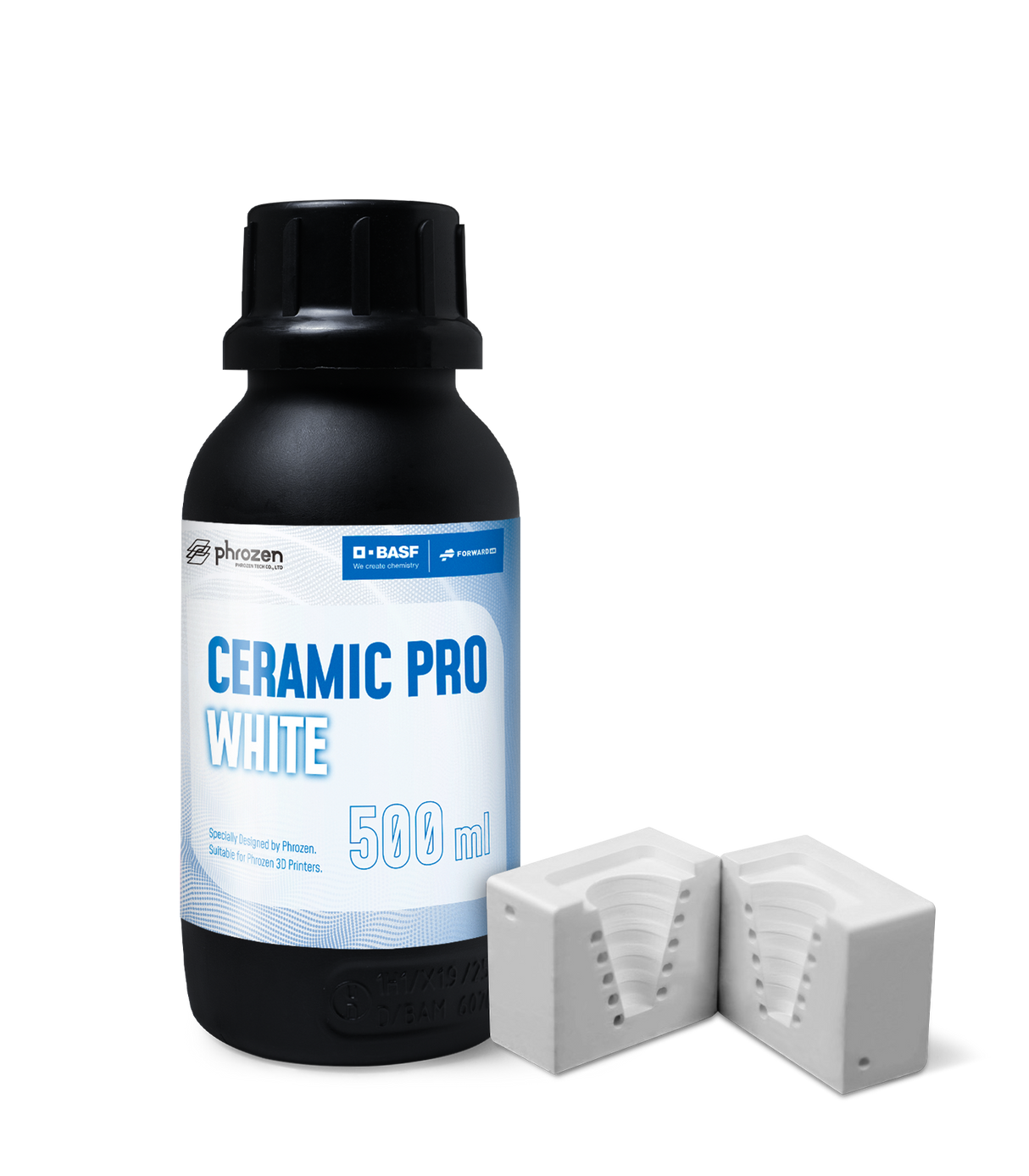

Phrozen Engineering Rigid Ceramic Pro

- Extremely rigid and heat resistant.

- Low viscosity, easy to print.

- Contains over 70% ceramic content.

- Best for injection molding core production.

Couldn't load pickup availability

Shipping & Tariff

- Please expect a standard lead time of approximately 1 week.

- Currently, the Phrozen US Store only ships to the mainland United States. For non-contiguous states and other U.S. territories, please purchase through our Global Store.

- No refunds will be provided if a customer refuses to collect or returns their product(s) due to related costs.

- Customers are responsible for customs clearance in all countries.

- For more information, please refer to our Shipping page.

Return & Warranty

- According to the Consumer Protection Act, you have the option to request a refund within a period of 13 days. However, please note that the refund does not cover the shipping fees and tax/VAT charges. To initiate the refund process, you need to submit a request to the Phrozen Support Center within this 13-day timeframe. It is important to ensure that the product is returned in its original condition, and the entire batch order must be sent back. For more details, please refer to our Refund Policy page.

-

All products purchased from the official website of Phrozen are warranted under different terms. Phrozen offers a one-year warranty for all our products except consumables and components; this includes the LCD screen and the FEP film. LCD screens for the Sonic Mighty 8K, Sonic Mini 8K, Sonic Mega 8K, Sonic Mini 4K, and Sonic 4K are covered under a 3-month warranty. For more details, please refer to our Warranty page.

*Kind reminder: We would suggest pairing our printers with Phrozen's resins to prevent surface paint damage. If a problem occurs, please feel free to contact our support team.

Precautions

Precautions

- Make sure to preserve resin at room temperature. Store in dark and ventilated conditions.

- After printing, please keep used resins in a closed & opaque bottle.

- Avoid mixing used resin with new resin.

- Keep resin away from kids and away from direct sunlight exposure.

- Wear gloves and masks when using resins.

- If this chemical contacts the skin or eye, wash with plenty of water.DO NOT dump resin.

- Please cure it and treat it as general plastic garbage.

Resources

Resources

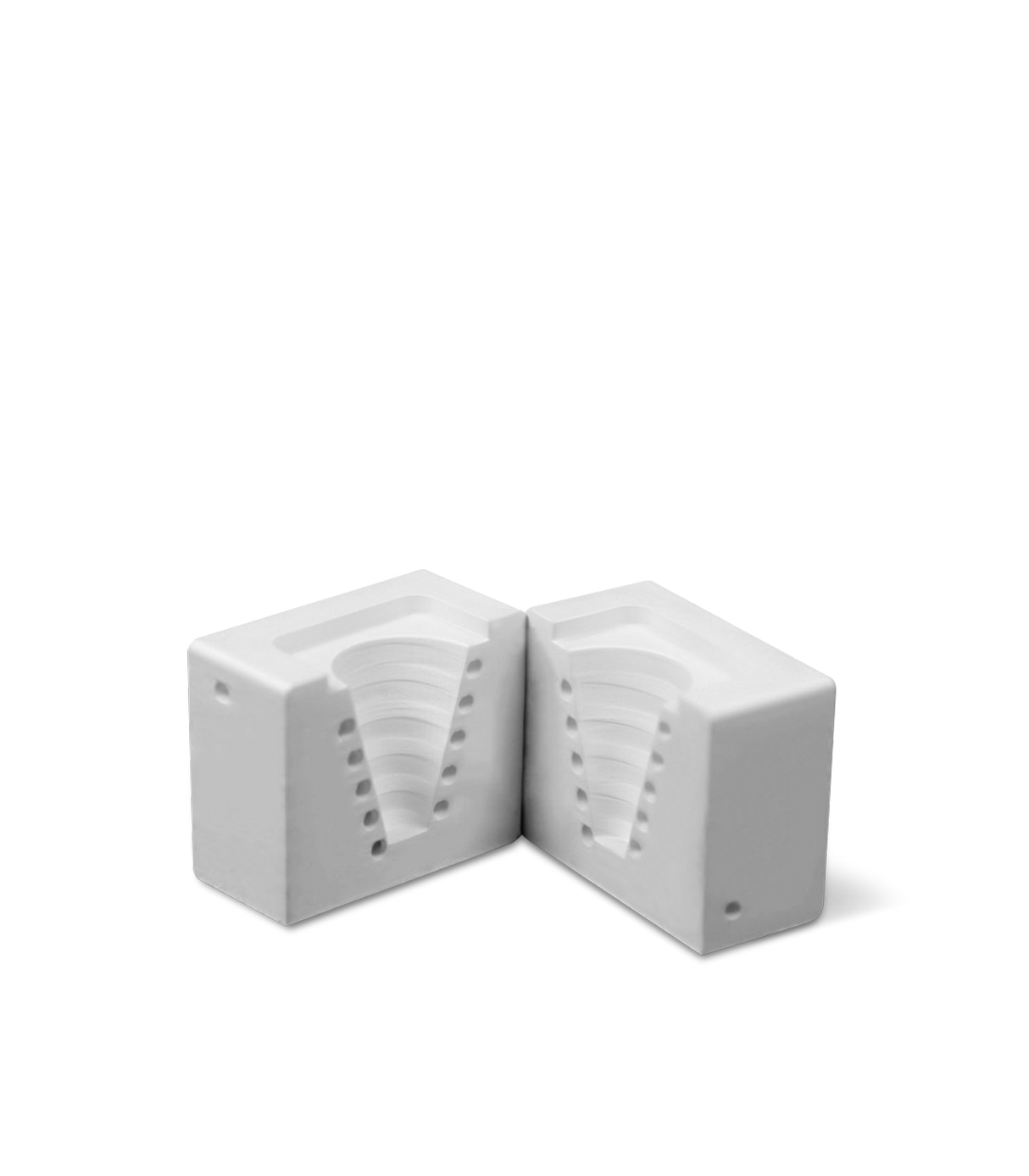

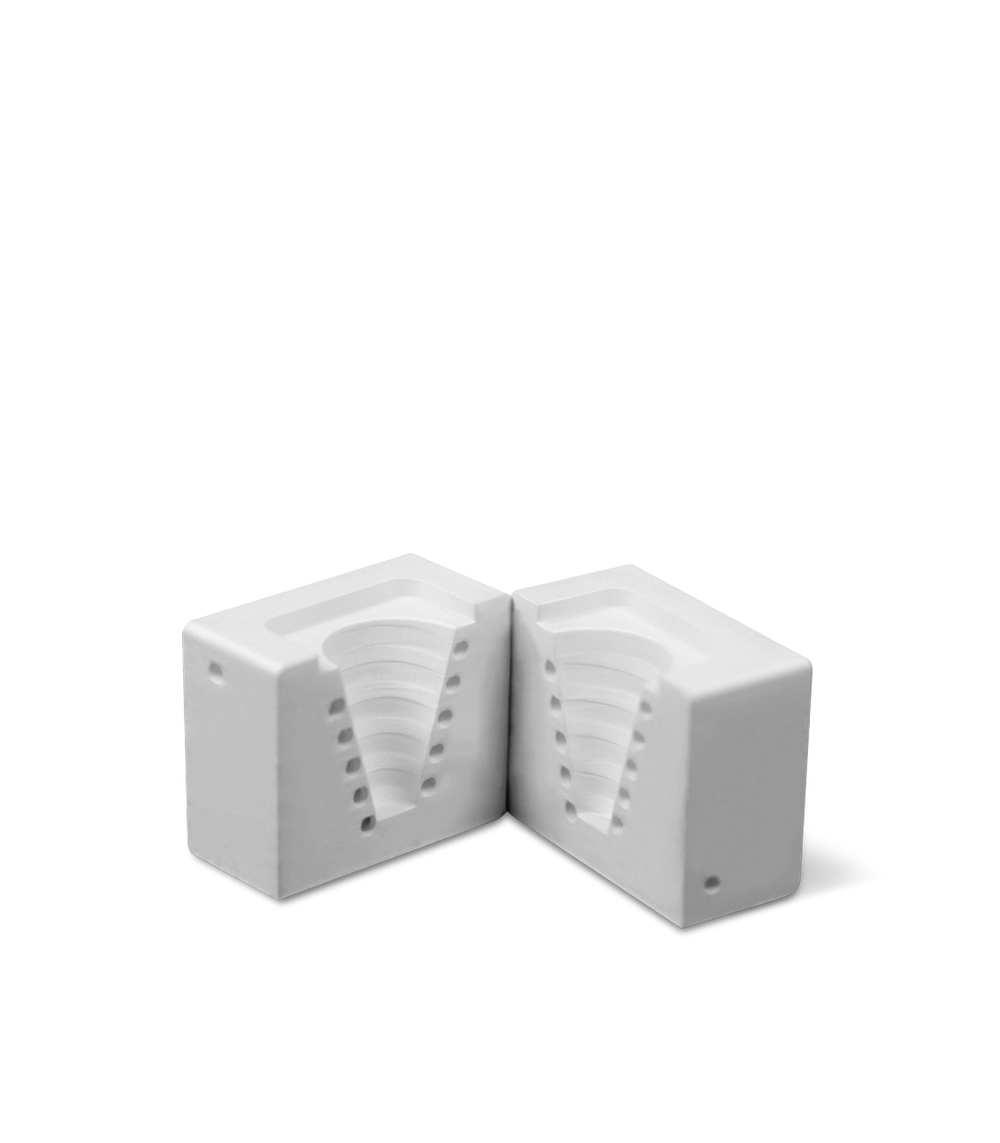

Reliable Properties for Injection Molding Mold

With extreme stiffness and great heat & chemical resistance, Ceramic Pro Resin is easy to print and a great fit for injection molding mold production.

- 280°C heat resistant

- 10086 MPa flexural modulus

- 230 cps viscosity (@ 30°C)

- Over 70% ceramic content

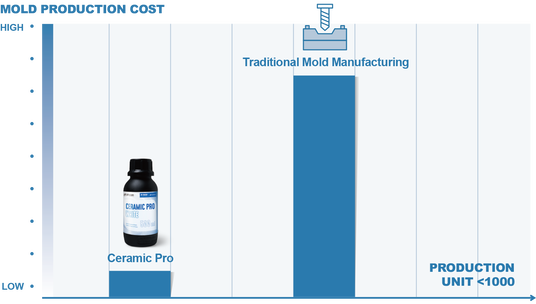

Unlock Accessible, Efficient Manufacturing Options

Ceramic Pro Resin complements traditional injection molding manufacturing by offering a flexible, cost-effective alternative for small-batch and custom production, making high-quality mold manufacturing more accessible to a broader range of applications.

Saving Production Time and Cost by 80%

By eliminating high MOQ requirements, long lead times, and extensive tooling costs typically associated with manufacturing, Ceramic Pro Resin reduces mold production time from weeks to under a day while saving up to 80% of production costs.

3D Printing vs Traditional Method

Small Batch Injection Molding Production

Learn How 3D Printed Mold Enhanced Productions

Overmolding

Ceramic Pro Resin is suitable for overmolding cable production, providing a fast, cost-effective solution to produce functional mold inserts with high precision and durability. It reduces production time to 3-4 days, minimizes costly mold iterations, and saves over €5,000 in overheads.

Injection Molding

While traditional milling costs up to €6,000 and takes 4–6 weeks, RC car molds with Ceramic Pro Resin cost just under €500 and are ready in about 9 hours. Its superior stiffness and high HDT offer a faster, cost-effective alternative to traditional tooling.

Image credit: SKZ – DREIGEIST – 3AM-Racing

Get the Best Out of Your Ceramic Pro Resin

Cleaning and Drying

1.Remove any trapped resin from holes in the model.

2.Wash in 99% IPA until it’s thoroughly cleaned for 30 – 60 seconds (don’t soak for more than 60 seconds to avoid surface damage).

3.Dry the model with an air gun or use the drying function in Phrozen Curing Station for 10 – 30 mins.

*When printing flat on the building plate, remove the printed objects carefully to avoid deformation on the objects.

*Remember to clean the inner parts of hollowed objects thoroughly.

Post-Curing

Cure the models in a post-curing unit for 120 minutes (60 mins/per side) for best results.

Thermal Curing

Perform thermal post-curing to enhance the mechanical properties of the models by baking them in a precise temperature-controlled oven (±2°C tolerance) by following the settings below: